|

|

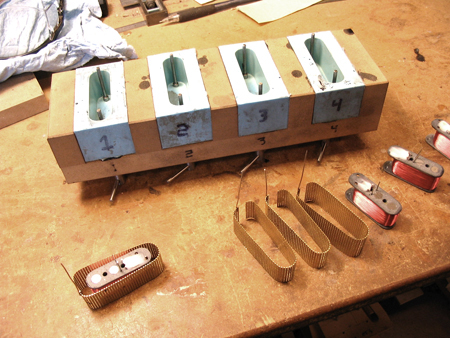

The M-pickup coils and shells get permanently cast into black epoxy. This is done in a set of silicone molds, made to the final oval shape. The molds fit into this wood frame to prevent them from swelling out in the center as the epoxy cures.

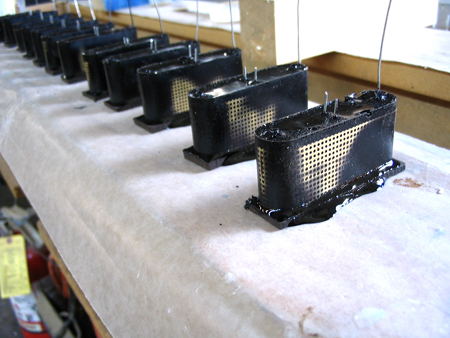

With the coils and shells in the molds, the epoxy is carefully poured in. For this application, I use West Systems epoxy with the slow #206 hardener, with some black powdered aniline dye to color it black. The trick is to minimize bubbles while stirring and pouring the epoxy. It takes about 12 hours to cure.

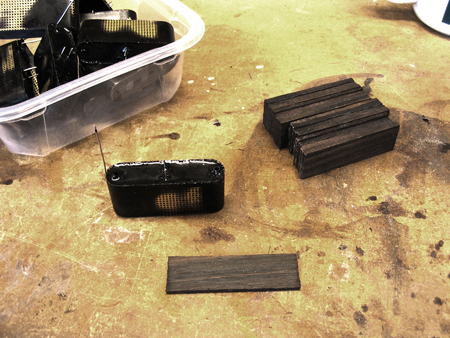

The pickups are glued to the ebony top caps with more black epoxy.

Final cleanup: A light touch against a finishing wheel cleans the excess epoxy off of the brass shell and leaves it as a satin sheen. Then, a drill and counterbore are run down through the mounting screw holes.

|

|

|

A pair of machined steel pins protrude up through the bottom of the molds to accurately locate the holes for the pickup mounting screws. These are waxed, and the mold is sprayed with mold release coating before the parts are put in.

The raw pickups out of the molds. Small strips of Macassar Ebony are cut, which will become the top caps.

The top cap is trimmed to size and the edges lightly rounded off.

A group of four M-pickup coils is assembled together onto a pair of aluminum mounting bars, using machine screws and short lengths of silicone tubing. I prefer silicone tubing over steel springs because the tubing can't ever rattle or buzz. The black foam rubber strips go between the coils to prevent them from rattling against each other. The M-pickup assembly is done!

Next Page..

|

|