|

|

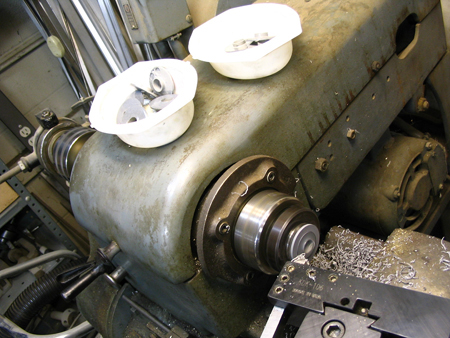

As with the M-pickups, the raw castings for the P-pickup bobbins get several machining operations. The back faces are turned flat in a lathe, and then the holes are drilled for the wires and terminals.

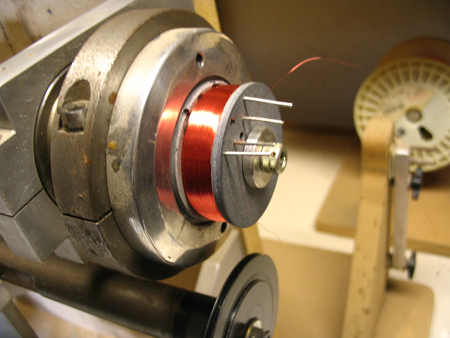

The bobbins are mounted to the spindle of the coil winder with a single screw and retainer through the center. They get 14,000 turns of #41 wire, which takes about ten minutes.

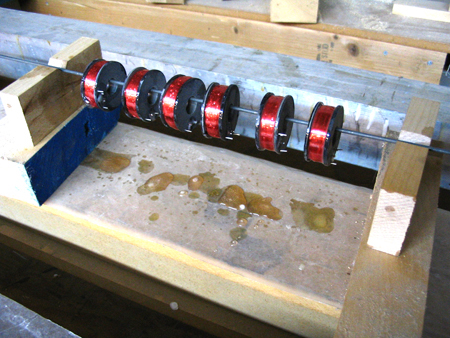

The coils are potted with MultiWoodPrime epoxy. Because these coils don't get any other outer shell, I also wipe on a light coat of West Systems epoxy for mechanical protection.

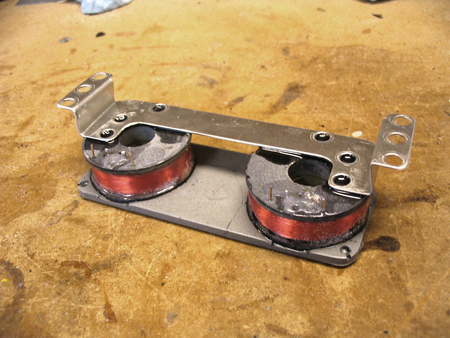

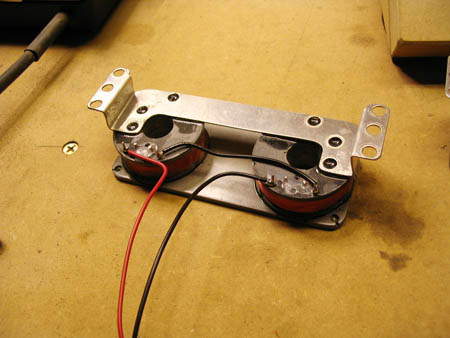

Two coils are glued into position on the base and the bracket is glued on top, all with West Systems epoxy.

|

|

|

I designed these bobbins so that the terminal blocks are built right in to the upper flange. Recesses are cast into the inside of the flange, and small loops of buss wire are fitted and glued in. When in place, they are flush on the inside surface. This is done only on the upper half of the bobbin. The terminals provide mechanically solid points for soldering the ends of the magnet wires and hookup wires.

The ends of the magnet wire are cleaned and soldered to the terminals.

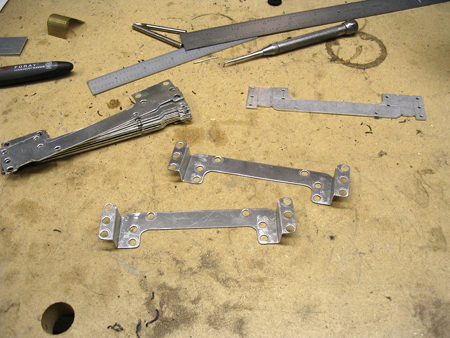

The top bracket is made from 0.030" aluminum sheet. They are sheared, punched, sawn, filed, and bent to shape to match a master template.

The lead wires are soldered to the terminals, and the coils assembly is tested.

Next Page..

|

|