|

|

The shafts of the pots have to be shortened about 1/4". This simple holding fixture fits in a vise and clamps the shaft while I saw it off with a hacksaw.

This is the wiring fixture that I made up. It holds the pickups and control plate upside down in the correct relation to each other, so I can make the harnesses fit neatly. It'll hold either left hand or right hand harnesses. I built it up at that angle to reduce neck strain!

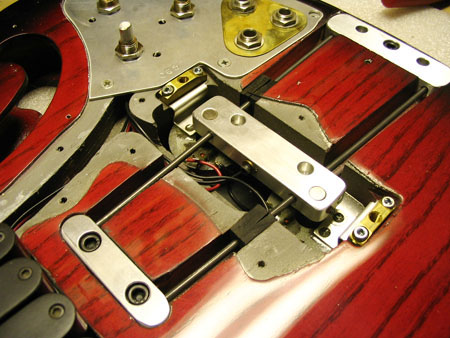

The P-pickup frame, including the magnets and rubber damping blocks, is installed in its recesses over the P-pickup coil assembly. Three machine screws hold it tightly down to the aluminum anchor blocks embedded in the body. The tailpiece also fastens down to the rear anchor block, through the rear block of the P-pickup frame. Mechanical rigidity is really important here. The frame is checked for movement and clearance. A ground wire from the control plate connects to the center block of the frame to ground the strings through the bridge.

|

|

|

Here are the pots and jacks assembled to the control plate. The thin triangular brass plate around the input jacks is just for looks; it shows through the opening in the pickguard.

Installing it in the body: The M-pickup and P-pickup assemblies are set down into their pockets and fastened down with socket head machine screws. The P-pickup mounting bracket is held down by the two brass blocks which also provide the threads for the bridge cover screws.

Finally, the system is closed up by screwing down the control plate and two cover plates. It's all tested through a bench amp before going any further.

Back to start of Pickups

|

|