|

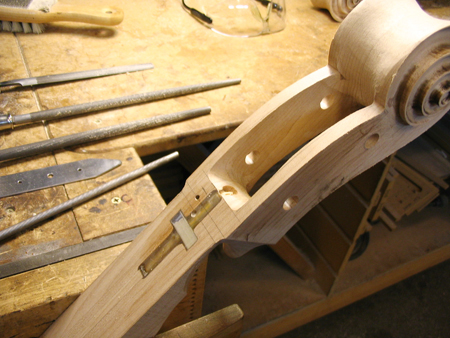

The concave surface is smoothed out with bent files.

The inside ends and corners of the pegbox are all contoured and blended with files. This is about two hours of work per neck.

Files are used to shape the inside of the side walls of the pegbox, which get thinner towards the top.

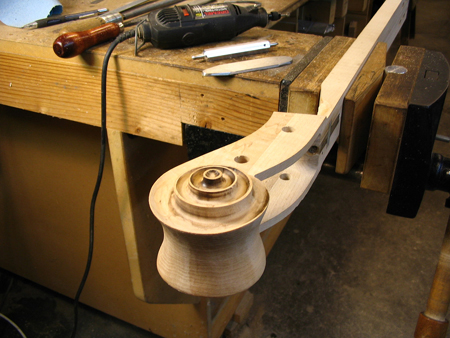

The sides of the headstock are carved last. Here, the outer lip is roughly blended and flared out to make a clean outer edge, using a Dremel tool with a small round cutter.

This is what the outer lip looks like, shaped and smoothed. The hard part is getting the edge to flow in a smooth, appealing curve, when looking at it from any angle.

|

|

|

The scoop of the tongue on the back is also roughly shaped with the die grinder, then smoothed with files and scrapers.

Bent files and special scrapers are used to smooth out the surfaces and bring them to fair, symmetrical shapes.

The same is done from the back, blending the side beams into the head and the heel.

A small specially ground scraper is used to smooth the fillet up into the edge.

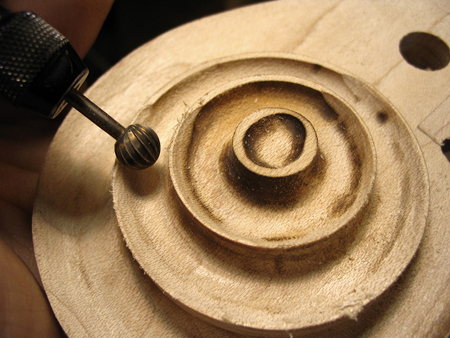

Finally, the rings of the scrolls are flared out to fine edges, starting with the Dremel tool. A steady hand is needed here!

|

Next Page..

|