|

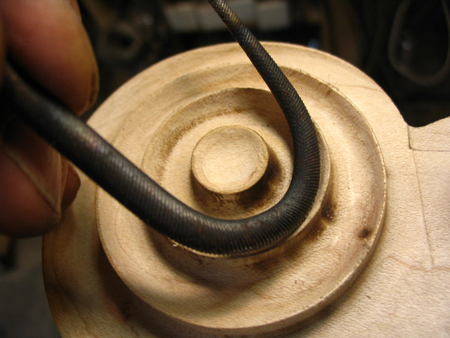

Here's a special tool for getting the inside fillets of the scrolls even; a round #2 Swiss pattern file, which I've bent into a loop using a torch.

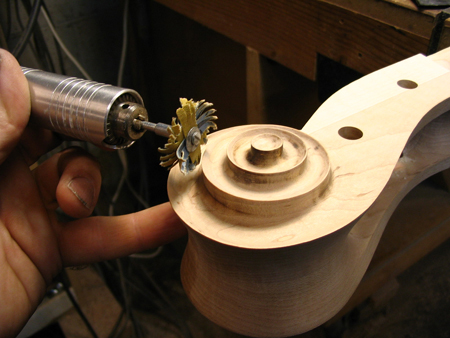

The final sanding of the scrolls is done with a miniature flutter wheel that I make up from strips of 220 grit sanding cloth, mounted on a small arbor.

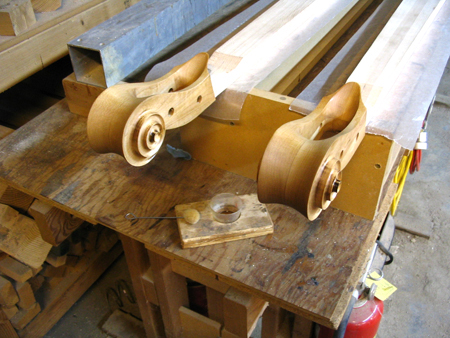

Two finished headstocks, representing about 12 hours of work each to this point. I've found that it's easier to complete the entire headstock first, before starting on the rest of the neck.

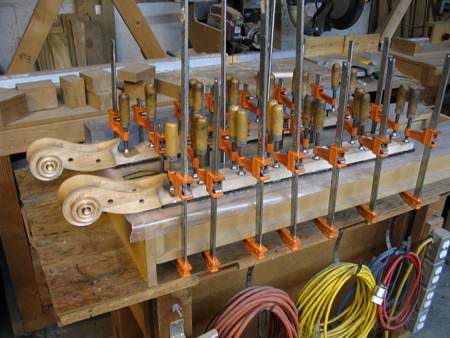

On to the rest of the neck! This fixture is used with a router to cut the two surfaces on the neck heel that mate with the pocket in the body.

This fixture is used to trim the sides of the neck straight and to the correct width and taper.

|

|

|

After filing to smooth out the shape, this tiny special scraper is used to remove the file marks. The scraper is made from a piece of 3/16" drill rod, ground to shape, and fitted into an aluminum handle.

At this point, the entire headstock is gone over carefully with #2 Swiss files to check for any bumps or waves. Under a gloss finish, it has to be perfect! Most of the surfaces are lightly sanded to 220 grit.

The completed headstocks are given a coat of Smith's MultiPrime, which is a special epoxy with a viscosity like water. It soaks into the surface of the maple, hardening it somewhat, and providing a good base for the paint to bond to.

After fitting the brass anchor bars into their pockets, the ebony fingerboard blank is fitted and glued to the neck with Smith's epoxy.

The corners of the heel and the lower heel surface are rounded off by hand with files, and checked with radius gauges.

|

Next Page..

|