|

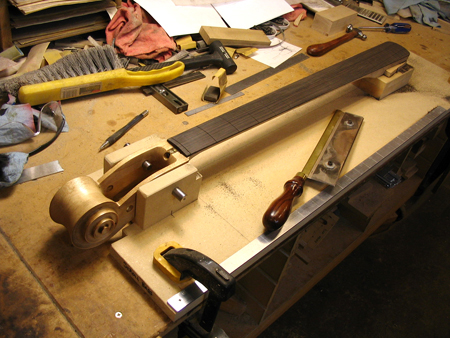

A template is used to draw the rough profile of the neck, and the neck is held in this fixture to bandsaw off the excess.

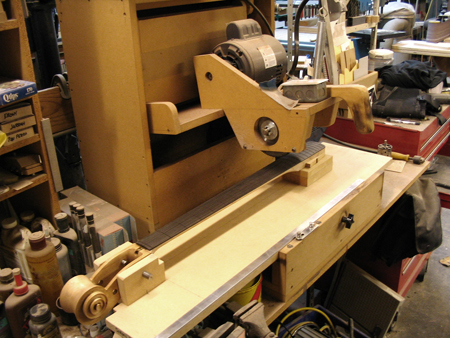

I call this contraption the Neck Horse. It's a specialized saw horse that holds a fixture on top, which holds the neck. It puts the neck a comfortable working height and allows full access while shaping it. I use an angle grinder for quickly roughing off some of the wood, but hand files are used for most of the shaping.

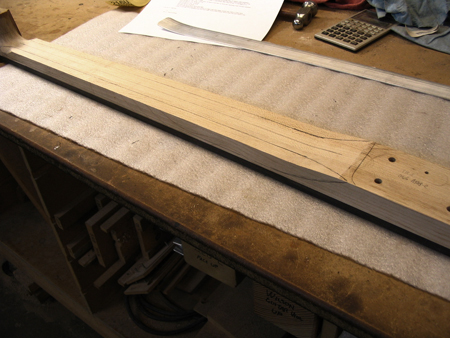

Here's the neck with all of the facets cut. You can see how they describe the transition of the shape from the heel to the headstock. When the facets are all true and flat, I use files to gently round off the ridges between the facets, and bring it to a smooth shape.

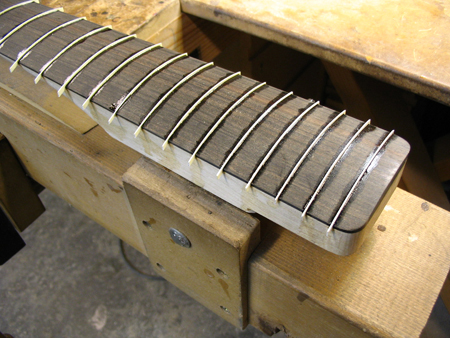

Here is the fingerboard after radiusing and light sanding. I use a 4" radius on my Scroll Basses.

A hand fret slot saw is used to clean out the slots and verify the depth of each.

|

|

|

I hand shape my instrument necks by first cutting them into five flat facets. These facets are particular angles and widths, and they twist slightly along the length of the neck. This is the best technique I've found for accurately laying out a complex 3-D curved shape. Here, the edges of the primary facets are drawn out on the neck.

Here, the primary facets have been cut and filed smooth, and the secondary facets have been drawn on the neck.

This special fixture is used to trim the fingerboard down to thickness, and cut the radius on it. Like the back of the neck, the radius is cut first as a series of flat facets first, then rounded off. The neck is held in the fixture with the truss rod pre-loaded to about 80% tension to assure that the truss rod's adjustment range will be correct under the strings' loading.

Necks for fretted AEB-2 models go into this fixture and machine, which cuts the slots for the frets. Another special machine of my own design, it cuts the slots at the correct depth while following the fingerboard radius. The fixture is indexed to the fret positions by the precision aluminum scale.

Here is a fretless AUB-2 neck that was ordered with optional white marker lines. In this case, slots are cut as if it were fretted, and then small arcs of 0.020" white styrene plastic are cut and glued down into the slots. When dry, they are trimmed off and sanded flush with the fingerboard surface.

|

Next Page..

|