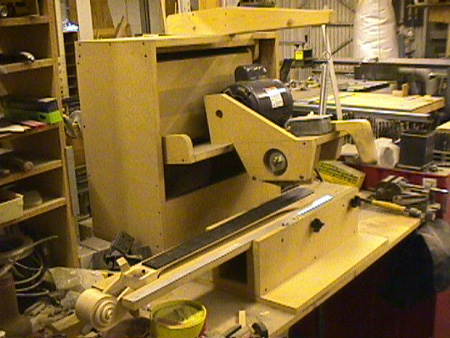

This is the fixture that cuts the basic shape of the scrolls in the maple headstock block. A series

of eccentric disks snap onto the base of a router, which is fitted with a special shaped bit. The

router rotates in the recesses in the fixture, cutting the rings of the scrolls. Two necks are

mounted in the fixture; after cutting the left side of one and the right side of the other, they

are swapped in position. This operation establishes the basic rings, but the final flaring and

blending is done by hand.

The ebony fingerboard is glued on using a special epoxy.

The back of each neck is shaped by hand using a spokeshave, special planer rasps, and files.

This is a fixture I call the "neck horse", which holds the neck in a comfortable working

position, with plenty of clearance for the tools.

|

|

Here, the neck is mounted in a special rig that applies load to match the string tension,

and a router with a special base is used to cut the radiused surface of the fingerboard.

This special saw cuts the slots for the frets, following the radius of the fingerboard and

indexing to the correct spacing. Developing this saw was a project in itself, but it's a real

time saver.

After applying a thin bead of liquid hide glue to the slots, the frets are tapped into position

and then pressed in place using a modified arbor press.

|

|